A 20-person digital manufacturing company has overhauled its business model to become one of the largest producers of reusable face shields in the U.S. ZVerse is currently producing about 100,000 shields per day. ZVerse Founder and CEO John Carrington projects the company will produce 20 million shields by July.

After hearing from local hospitals, Carrington sprung to action to build a strong domestic supply chain and to meet demand for personal protective equipment (PPE) – specifically face shields. Leveraging ZVerse’s digital manufacturing ecosystem, Carrington brought together designers, materials and manufacturing partners, including Protolabs, the fastest digital manufacturer in the U.S. (NYSE: PRLB), to accelerate mass production.

“The need for face shields is dramatic and urgent,” said Carrington. “Our lives transformed overnight as we mobilized our network to get as many shields as possible to the front lines. We are hearing from hospice workers, anesthesiologists and other medical personnel who are desperate to order protective gear for their employees. Our critical care community is vital and vulnerable. We are working hard to shield them as quickly as we can.”

Carrington is investing $4 million in upfront capital expenses, which include the professionally engineered injection molds. Initially, ZVerse used 3D printing to produce the first 1,000 shields. However, the overwhelming demand led the company to use injection molding to increase production to 100,000 shields per day at a price hospitals can afford.

“We’ve been working with ZVerse from day one on this project,” said Gurvinder Singh, Injection Molding Product Director at Protolabs. “We were able to leverage our digital injection molding process to go from CAD to production in 48 hours and have been delivering thousands of critical parts every day since then.”

ZVerse has orders from hospitals and government agencies for nearly 3 million shields. Customers include Prisma Health, Veterans Affairs, Concourse Federal Group, the state of South Carolina, Kaiser Permanente, South Carolina Department of Corrections and Roper St. Francis Healthcare. First deliveries went out on March 31 to Prisma Health.

“Prisma Health was an early customer with our order for 50,000 shields,” said Matt Rivers, supply chain manager at Prisma Health. “We were looking for reusable, easy-to-clean face shields that could be produced in large quantities quickly. ZVerse’s domestic supply chain gave us confidence in its ability to deliver. With the initial 500 shields arriving last week, our nurses, doctors, respiratory techs and other clinical providers are now using the face shields to treat our COVID-19 patients.”

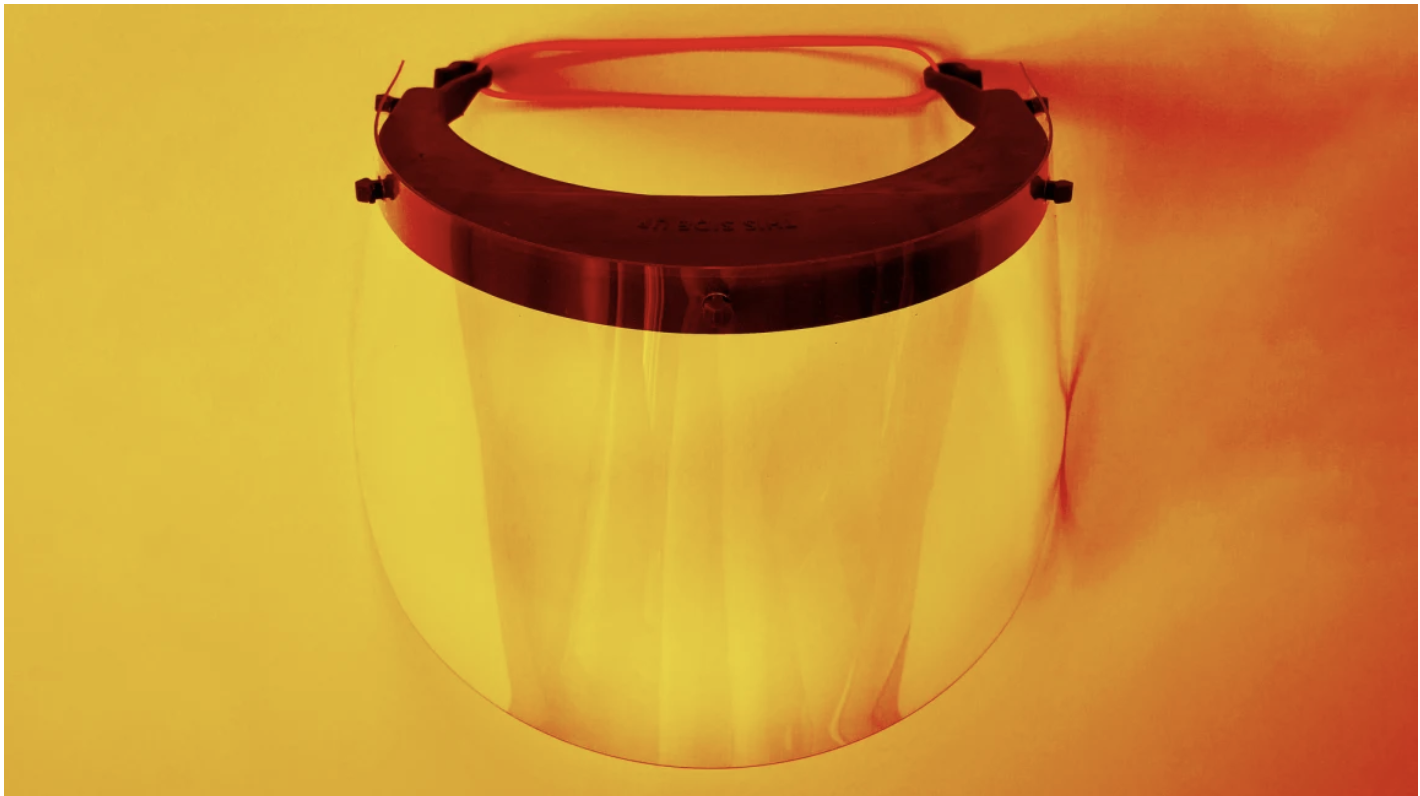

In addition to bulk orders, ZVerse has made shields available for the general public to purchase in single quantities, 5-packs or 10-packs. They are designed to be reusable and to protect the face, mouth and eyes from spray and splatter. Each unit comes in three parts, a headset, visor and application band. The shield takes 30 seconds to assemble.

The shields are designed, sourced and made in the U.S. According to Carrington, it’s critical to create a strong domestic supply chain that isn’t hindered by international shipping or customs interference. In addition to its 20 team members, ZVerse estimates hiring at least 50 people in South Carolina as well as contracting local companies to help with sales support and logistics.

South Carolina Governor Henry McMaster said, “American business is overwhelmingly comprised of small businesses like ZVerse. The rise of these local businesses aiding in a time of need is a time-tested American story that tells us we will prevail. We are incredibly proud of the work ZVerse is doing to provide much-needed PPE and jobs to the state of South Carolina, and across the country.”

Read the Fast Company article here. For more information, follow ZVerse on Facebook, Instagram, LinkedIn and Twitter and visit the website BetheShield.info.